Thanks for the reply, Patrick!

I decided not to risk it and increased the size of the patches to 7mm. It’s using a little more of the print surface than I would like, but it will do.

I’m wondering, then, how the basePageDescription measurements are derived. They don’t seem to correspond to the .tif file at all. Perhaps they’re irrelevant in the context I’m condsidering.

Ah. Here’s where my knowledge of this automation is clearly falling short… My assumption was that the .xml file described where on the bed the target should lie, but what you’re describing implies that the target could be placed anywhere on the bed and there’s a “homing” procedure that tells the robitics where “home” is.

That one I’ve got figured out!  I’ve made a “template” out of thick plastic in which I’ve cut two holes. Luckily the iO has provisions for setting the stock thickness and the 1.2mm thickness of our disc (and the template) is well within that range. The idea is that we print the two discs, put them in this template and send the iO measuring away!

I’ve made a “template” out of thick plastic in which I’ve cut two holes. Luckily the iO has provisions for setting the stock thickness and the 1.2mm thickness of our disc (and the template) is well within that range. The idea is that we print the two discs, put them in this template and send the iO measuring away!

Here’s the general idea of what I’m trying to accomplish; I’m a visual kind of guy so maybe this will help those who are as lost about this as I am about the iO!

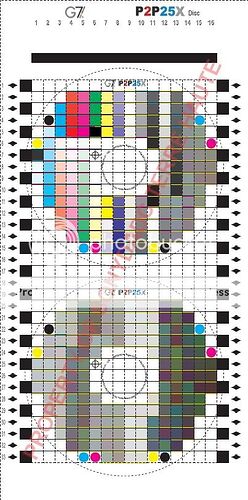

The P2P25X file has been split on to two discs:

I then created this template (not knowing what features of the original image aided the iO in locating the patches, I duplicated all of them I could):

The idea is that I would print the two discs on the same press, no adjustment, back to back in one “session” and then place them in this template on the iO bed. (It would look something like this):

(Sorry for the hideous watermarks… legal considerations and all that.)

With the right software (or butchering of the .xml file) I would measure all the squares, creating a very messy .cie file. (Assuming I use basICColor Catch for this task)

I’m a programmer by trade so the process of turning 528 patches into the 300 that are actually used in the P2P25X is actually the easy part! Finally, then, I will have the files required to use in the Curve 2 software.

Sound reasonable?

-Brian